Introduction

Chips or chips?

It seems that recently nearly everyone knows the difference between potato chips and semiconductor chips. Politicians and policy makers have suddenly woken up and realised semiconductors have to be at the centre of their strategies.

All this noise around semiconductors has been a real relief for me. Finally, people are beginning to know what my job is all about!

COVID-19 has affected society in countless ways, one of the most significant is increased digitalisation. Some say that the pandemic has accelerated this process by a decade, leading to the current semiconductor shortages. At Flusso we want to capitalise on this drive towards digitalisation as an opportunity to deliver an even more positive impact on society and the environment.

Smart technologies have been a trend for the past two decades with the promise of improving people’s lives and safeguarding the planet. Such technologies are capable of gathering, processing, securely transmitting, and acting on enormous amounts of information.

Semiconductors are crucial for this, but you know what’s the best part of this story? That sensors, and in particular MEMS sensors are at the core of it. They enable the information to be gathered in the first place. No sensors no party! And MEMS sensors are in the Flusso Team’s DNA.

At the recent Sensors Converge fair in San Jose, where we were also a finalist in the ‘Best of Sensors’ awards in the MEMS category, we were surprised by the breadth of different applications that were coming our way. From home appliances and HVAC control in buildings and vehicles, to safety and combustion control, all of these products are getting smarter.

Is flow important in your application? Do you need to monitor carbon dioxide for air quality purposes? Or maybe methane or hydrogen?

Using our sensing technology platform we’re making flow and gas sensors with tiny form factors, with the right performance and price point so they can be integrated into virtually any end-product you can think of.

Join us in our mission to give people more time for what really matters to them: to be healthier and to live in a greener environment.

Andrea | CEO and co-founder

Manufacturing news

Flusso starts volume shipments

It’s been a busy few months for Flusso’s operations team as we’ve advanced into volume production and have started shipping to multiple customers across the world.

Most flow sensors and modules are still manufactured within a company’s own facilities, whereas the FLS110 has been designed from the start as a semiconductor component for fabless manufacture. It means we can manufacture and test our devices using a short and super-efficient supply chain that’s fully optimised for low-cost, high-volume production.

Flusso has established an automotive-qualified supply chain, comprising of world-leading suppliers in MEMS, device assembly, and fluidic testing.

Our sensors are manufactured using standard foundry processes, and we’ve even developed one of the industry’s most comprehensive test regimes for flow sensors using readily-available equipment. Every single device is automatically inspected, then tested electrically and fluidically to guarantee quality.

Flusso’s manufacturing approach means we can scale rapidly to millions of devices per month, and without needing to pause while we wait for additional facilities to come onstream. We can do drop shipments and even maintain buffer stocks to help customers during the introductory phase.

The FLS110 has been designed as the world’s smallest flow sensor to provide the ultimate in design flexibility. But also to be manufactured in a much more time- and cost-efficient way to perfectly align with all our customers’ needs when developing new high-volume consumer, medical or industrial products.

Please contact sales@flussoltd.com or click below to order an evaluation kit to test the FLS110 within your application.

Cerdin Lee | Operations Director

Product news

NEW evaluation kit for drone airspeed

Fixed wing drones are revolutionising many industries at the moment. They are being used to deliver COVID vaccines in rural Africa, surveying railways in Switzerland, mapping sand dunes in California and even monitoring the effect of climate change on glaciers and ice sheets in the Antarctic. With such an enormous range of applications, it shouldn’t be surprising that the drone industry is expected to grow 50% year on year until 2028.

No matter the application, fixed wing drones rely on accurate airspeed measurement to predict battery endurance and optimise their range. Knowing exactly how far the drone can fly and the trade-off between speed and range is critical as these drones take on ever more demanding missions, often fully autonomously.

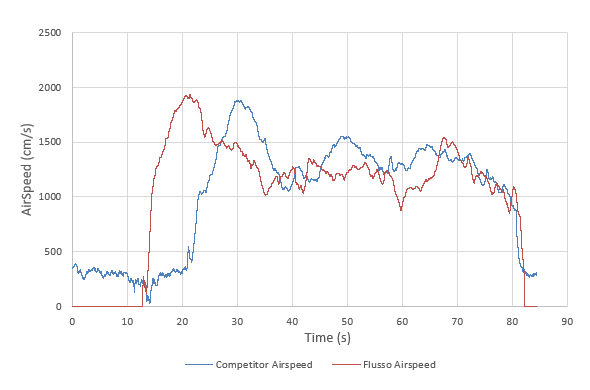

The extremely small size and weight of the FLS110 makes it very well suited for drone airspeed applications and it outperforms existing differential pressure sensors significantly. In order to achieve the best possible accuracy in this application Flusso has implemented what we believe to be an industry first: pressure compensation for a thermal mass flow sensor.

This allows the data from the barometer on the drone to be used to further improve the accuracy of the airspeed measurement across a wide range of altitudes. The low cost of the sensor, and its suitability for high volume manufacture, allows the FLS110 to scale fast enough to keep up with the mind-boggling growth of the drone industry.

Managing evolving requirements is a key challenge within the sector. But there are two specific aspects of the FLS110 that have enabled rapid, agile development of bespoke solutions for many different types of drones and other applications, both within Flusso and by our customers.

Firstly, its ability to measure mass flow, volume flow, differential pressure, and airspeed; and secondly, the FLS110 can be customised and configured entirely in software using our software development kit (SDK).

If you’d like to evaluate the FLS110 for drone applications then we have a specially-designed evaluation kit that can help. We’ve developed an FLS110 sensor module airspeed fluidic adapter with pressure sensor port that works with an off the shelf pitot tube.

Please contact sales@flussoltd.com to get more details on this specific kit or click the link below to learn more about our other evaluation kits.

Chris Rosser | Head of Systems and Applications

Events

Let's meet in Las Vegas!

If you’re heading to Las Vegas for the largest and most influential tech event on the planet we’ll see you there!

It’s just been announced that Flusso has been selected to feature at Eureka Park, CES 2022 (5 to 8 January). We’ll be on booth #63345 in Sands G showcasing some of our latest applications and sensor technology breakthroughs, and will announce more details on our website soon.

Distributors

Flusso appoints Arazim and Opto-Sensor

Flusso has signed two new distribution partnerships: with Arazim in Israel and with Opto-Sensor for Taiwan & China, both as technical distributors.

We welcome those new partners with excitement as we continue developing our channel strategy across the globe. If your company has specific distribution expertise in industrial, consumer or healthcare markets, and believe you can help us reach our goals, then we’d love to hear from you.

Please email us at sales@flussoltd.com

Amazing facts about flow

Hospitals still reliant on 'archaic' flow meters

When the world’s first variable area flow meter was invented by Karl Kueppers in 1908, it was initially proposed as an innovative way to measure water flow rates. It wasn’t until around 50 years later that various design improvements allowed the same fundamental approach to be used for the volumetric flow of gases.

Rotameters are based on a vertically tapered tube with a shaped ‘float’ inside that is pushed up by the drag force of the flow and pulled down by gravity.

The devices are used almost ubiquitously for flow metering in today’s hospitals and industrial environments but they’re not digital. And it’s an increasingly serious limitation in our connected and data-driven world.

Every single rotameter still needs to be regularly checked and monitored by a human during use to ensure it’s working as expected. Using a low-cost digital flow sensing solution, such as the FLS110, could be the perfect replacement for rotameters and similarly outdated flow measurement approaches.

The FLS110 allows real-time flow rates to be monitored, automatically adjusted and logged as required. It also allows flow measurements from multiple systems within a hospital, building or specific facility to be brought together onto a single platform: enabling faster, better and more-efficient decision making.

Get in touch

Please complete all fields

Please select your industry sector to ensure future communication is relevant to you.

Check box if you wish to receive Flusso Pulse regular news updates