Introduction

An exciting future together

I hope you are in a cool place. I have a cooling fan pointed straight at me in an attempt at fighting temperatures of over 30°C with extreme humidity too. And today is a good day. I don’t feel the heat that much though, because the team at Flusso is keeping my mind busy with fresh exciting news every day!

As you’ll read in this issue, we recently signed Tecnosens as our first technical distributor for Italy and Europe. And Digi-Key as our first global reseller. We have a few more distributors lined up around the world. But if you’re not one of them and think you can help, then please scroll down to complete the ‘Get in touch’ form.

We are also growing our technical team: Luke and Sean have just joined, Alison will be onboard soon, and we have two further vacancies to fill. Have a look here.

We’ve got feasibility studies underway for two more game-changing products. So stay tuned, we might announce one shortly.

And at the same time, more and more people are familiarising themselves with our FLS110 sensor. We’ve just launched a new evaluation kit. And our resources are being stretched with lots of enquiries for new applications such as drones. It’s probably my favourite problem though!

Helping people and the environment with our sensors is our goal, our purpose at Flusso. It seemed like such a distant goal when we started. But it’s getting closer.

It reminds me of a quote about success that’s been adapted from the inspiring book Lead the Field by Earl Nightingale:

Success is the progressive realisation of a worthy goal. Success does not lie in the achievement of a goal, but in the journey towards the goal.

If you share our goal, then let’s meet up at one of our events and work together towards it. Let’s feel successful together!

Andrea | CEO and co-founder

Product news

Flusso adds pressure compensation to FLS110

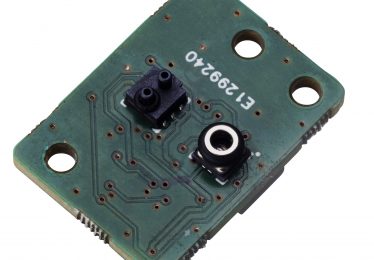

Flusso has just launched its FLS110 V6 Evaluation Kit with flow pressure sensing and support for volumetric flow and differential pressure readings.

This is the first time pressure compensation has been integrated into a MEMS thermal flow sensor. And it will enable the FLS110 to deliver class-leading mass flow, volumetric flow, differential pressure and air speed measurements, even as the environmental pressure and temperature fluctuate over a wide range.

This additional functionality is particularly critical in drone applications, where the outside temperature and pressure can vary greatly with altitude and an accurate air speed measurement is mission critical. However, any application that requires accurate flow measurement and experiences fluctuations in pressure or temperature due to altitude, weather or system changes can benefit.

The FLS110 is extremely flexible. It can measure:

- Flows as low as a few sccm up to 1000s of slm.

- Differential pressures as small as a few Pa up to several kPa.

- Air speeds up to 200 mph (324 kph).

The new FLS110 evaluation kit comes equipped with everything you’ll need to evaluate this unique functionality and the sensor’s performance including:

- USB to I2C adaptor;

- flow fixture; and

- sensor module that includes both the FLS110 and a MEMS pressure sensor

The kit is plug and play with any Windows 10 computer, and you can use our evaluation software to configure, calibrate, and log data from the FLS110. Click the link below to see how easy it is to set up.

Chris Rosser | Head of Systems and Applications

Webinars & events

Drone applications and Sensors Converge 2021

In our drone applications webinar – Thursday 9 September at 5PM CET – we’ll be discussing some of the design challenges manufacturers can face in getting accurate airspeed measurements. How the FLS110 with its latest integrated pressure compensation features can help. And what other steps manufacturers can take to help shorten their development cycles and to speed time to market.

Click the link below for further details and to sign up.

If you’re off to Sensors Converge 2021 – from Tuesday 21 to Thursday 23 September – we’ll see you there!

James, Thomas and other members of the Flusso team will be on booth #321 in San Jose. So come along to say hello.

We’ll be showcasing the world’s smallest flow sensor and unveiling new application demos including one showing use of the FLS110 in an air pump for a gas or hydrogen boiler. Our sensor experts will be on hand to answer any questions you’ve got too. And we’re all looking forward to meeting you.

Distributors

Flusso signs first two partnerships

Flusso has signed its first two distribution partnerships: with Tecnosens in Italy, as its first technical distributor, and with Digi-Key as a global online re-seller.

These two new partnerships are the first in a series of planned global and regional appointments we’re targeting for this year. But they’re just the start.

If your company has specific distribution expertise in industrial, consumer or healthcare markets, and believe you can help us reach our goals, then we’d love to hear from you.

Please email us at sales@flussoltd.com

Amazing facts about flow

Tesla’s best-known invention

When Nikola Tesla invented his bladeless, steam-powered turbine in the early 1900s, he relied on the viscous drag of a fluid passing over a solid surface to make the flat disc blades spin.

At first it was a very inefficient process. But he soon discovered that if the discs were brought close enough together, it improved the power transfer from the steam to the rotor. He even claimed efficiencies of up to 95% under ideal conditions!

Tesla is credited with over 300 patents for his multiple breakthroughs in mechanical and electrical engineering throughout his career. But it's his boundary layer turbine that remains one of his best known inventions.

The principles used to control the viscous shear forces between a fluid and a solid surface within the Tesla Turbine and Flusso’s FLS110 flow sensor are identical.

In the case of the FLS110, the sensor’s class-leading performance is controlled by the precise geometry in the tiny channel formed between the package lid and the sensor membrane. This geometry has been optimised using computational fluid dynamics and the performance verified with experimental testing using NIST-traceable reference meters.

We can only imagine what Tesla might have achieved with access to the same technology!

Image credit: Napoleon Sarony (from Wikimedia Commons)

Get in touch

Please complete all fields

Please select your industry sector to ensure future communication is relevant to you.

Check box if you wish to receive Flusso Pulse regular news updates